The History of Radyne

Radio Heaters Limited

During the latter half of World War II Christopher Tibbs and Edward Stanley owners of Radio Heaters Limited in Wokingham, England were developing radar equipment for the war effort, when they realised the benefits of utilizing high frequency electrical energy to heat metal without contact. They knew this method would produce a cleaner, more controllable and flexible system for heating metals and plastics. Previously Induction was not seen as an industrial process, however with the need to produce large quantities of parts for the war effort, with minimal labour the development of the process grew

The Birth of Radyne

Radyne was born in 1946 with the new company name being created by using the RAD from the word Radio and DYNE which is a unit of force. Their first employee Mr D Thompson an ex-Royal Airforce Officer started working for the company in February 1946 and from this humble beginning a mighty company grew.

The Radyne name soon became synonymous with induction heating and were rapidly known for their innovation and technically advanced products, which were exported to all corners of the globe. Winning numerous awards including being the first recipients of the “Electroheat Award for Innovation” from the National British Committee. By the mid-’50s their reputation grew exponentially, Radyne was a leader in its field and was considered largely a household name in European markets.

Specialists in Metal Induction Processes

Radyne developed specialist expertise in a wide range of metal induction processes including brazing, hardening, annealing, forging, tempering, extrusion, melting, wire hardening and annealing and welding but it also had a strong reputation in the field of plastic induction processes including shrink fitting, coating, plastic sheet welding and many more.

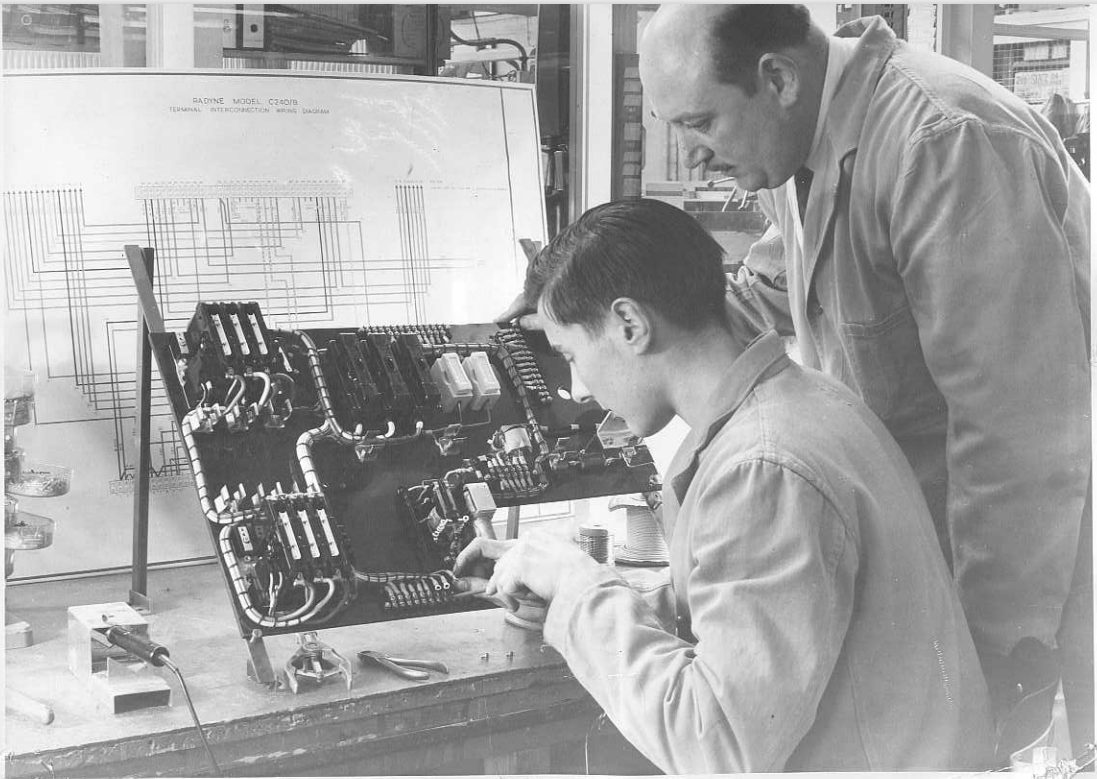

With customer needs at the heart of development, the products were conceived and designed by their team of engineers and draftspeople, who also created many of the new components, PCB’s and circuit boards from scratch in house. Such was the level of innovation that the parts needed were not available to buy and had to be made in the workshops. All this was done at a time when computers and CAD were not invented or remotely common in the workplace

Wokingham – Home of Radyne

At its height in the mid 1960s Radyne was one of the largest employers in Wokingham, England with over 750 employees working in their production factory on Molly Millers Lane. The company was a huge part of the town’s community and regularly took part in community carnivals and other community-spirited activities.

Radyne Incorporation

At this time the company had diversified with Radyne equipment also being built in Holland with sales, marketing and service operations in Ontario, Canada and in Chicago, Illinois, USA.

It was not until 1976 that Radyne Ltd, now represented in 27 countries throughout the world, decided to take a long look at the market opportunities within the United States and Mexico, resulting in the creation of Radyne Incorporation, created in North Canton, Ohio in 1978. This company later moved, via Elk Grove Village, Illinois, to its present location in Milwaukee Wisconsin where Radyne Incorporation purchased an existing company, AKO Manufacturing and changed the name through Radyne/AKO Corp. to Radyne Corporation as it stands today.

Further developments in the areas of ammunition bonding, hardening of shells, cartridge annealing, wire bright and dull annealing, hydronic valve soldering, hardening of caterpillar links, shafts, bearings, races, brazing of manifolds, fuel rails, fuel lines, extrusion of titanium, stainless, billet piercing, composite curing and many others continue to make the Radyne name unmatched in skill and knowledge.

Radyne is Acquired by the Inductotherm Group

In June 1991 Radyne Ltd the parent company was acquired by the Inductotherm Group an American company that also manufactures induction heating equipment. Inductotherm Group also acquired several other UK companies including Banyard previously based in the South of England, and Newelco previously based in Wales. In 2006 all three companies where restructured and amalgamated into its existing premise at the European headquarters and manufacturing site of Thermatool in Basingstoke and Inductotherm Heating & Welding was born.

Much of the Radyne knowledge, expertise and innovation has been retained in Inductotherm Heating & Welding, with many staff continuing to work from the Basingstoke site. Much of the Radyne equipment in the field produced prior to the amalgamation is still serviced and maintained by Inductotherm Heating & Welding.

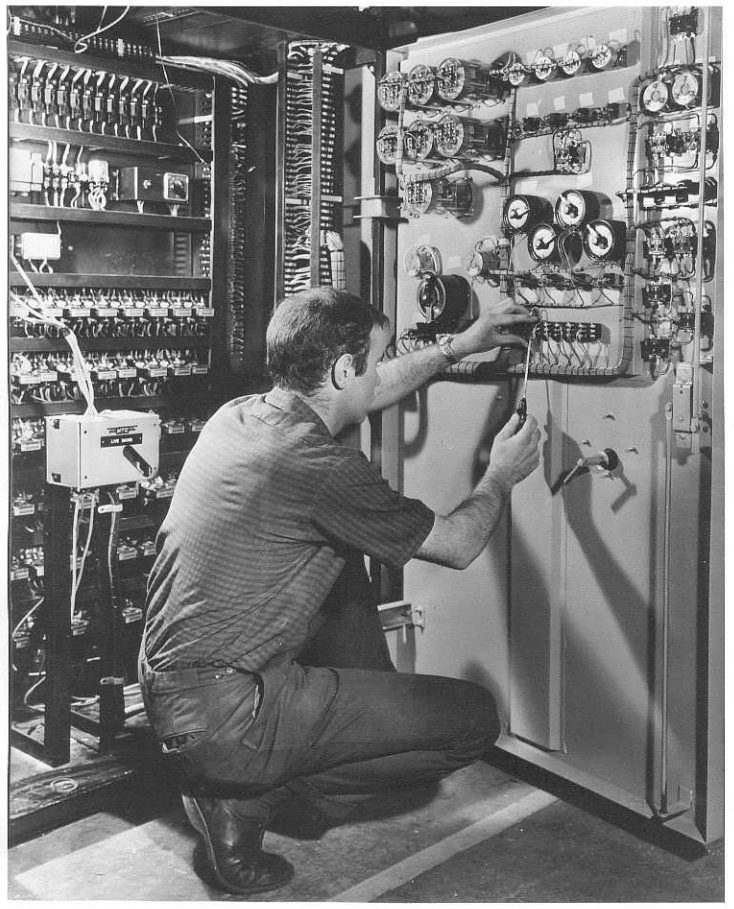

There have been many changes since those early years, for example, the elimination of vacuum tubes for the generation of high frequency electronic power, the incorporation of high power transistor type devices called thyristors (or very large solid state switches), a massive reduction in the size of the equipment as we move further into the electronic age, and semi-conductors allow us to reduce the size of the equipment by leaps and bounds as the years go by. The incorporation of microprocessors, electronic control circuits and programmable controllers, computer-controlled drives, and other sophisticated electronic devices are commonplace in the equipment that we manufacture. This is partly due to the industry demand, especially as a large proportion of these products are automotive related but is also incorporated in a desire to reduce the maintenance and floor space requirements for such equipment.

Innovations in new markets such as the offshore industry have been successfully entered, with the provision of our offshore product range including the Merlin field joint coating solution, which has been successfully installed on a number of high profile shipping vessels laying gas pipes in the worlds deepest oceans. In addition to the Merlin Radyne offers pre-heating clam coils, pipe end pre-heat equipment, containerised off shore induction solutions and hand held patch heaters.

Whilst some very old equipment has now been discontinued we are proud to state that we still have some 30-plus-year-old equipment continuing to work in the field today. We continue to support and replace this equipment with more modern and efficient alternatives in addition to providing spares, upgrades and servicing to our customers.

For more information on the Radyne products, we offer today click the link below