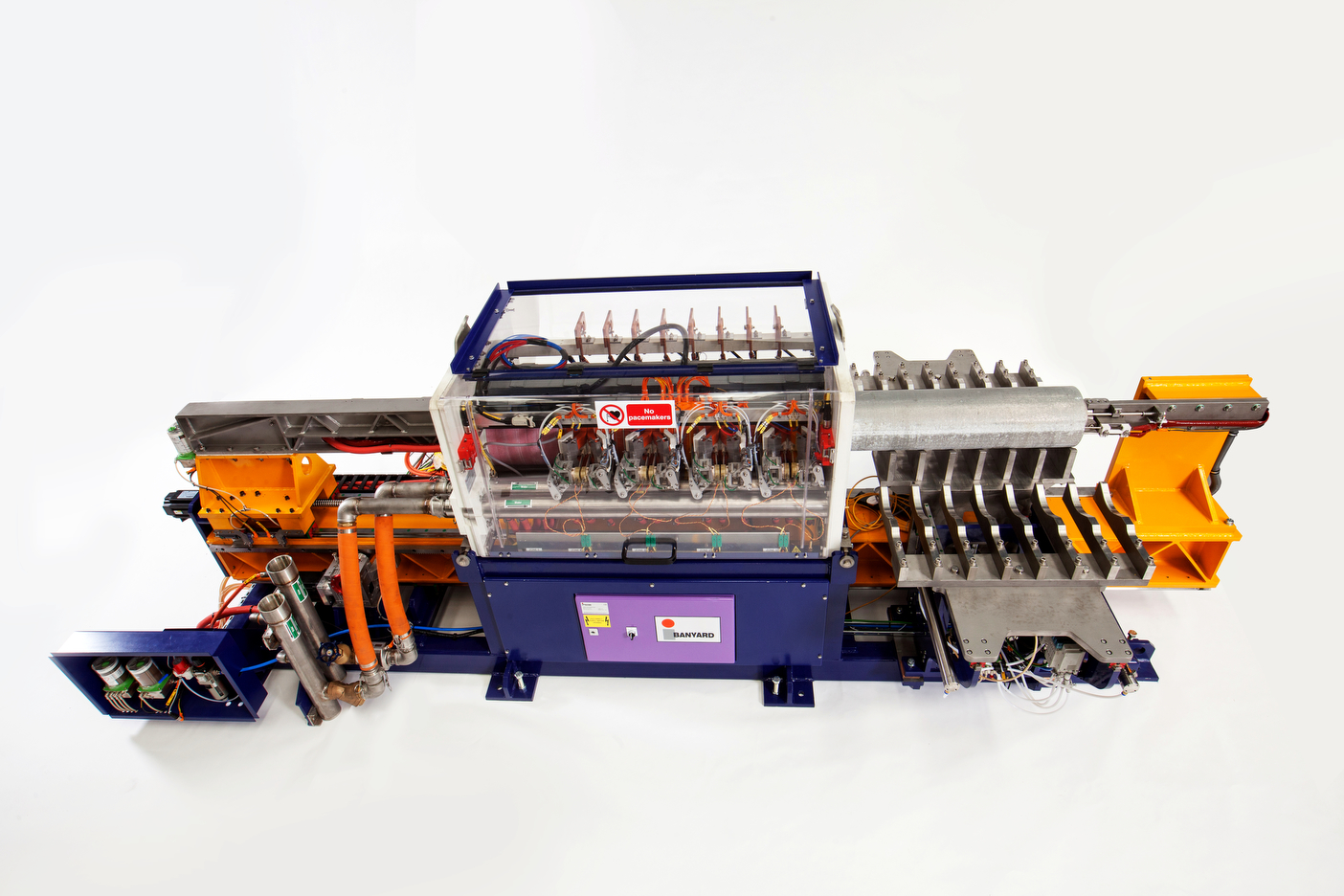

Zero Friction Aluminium Billet Heater

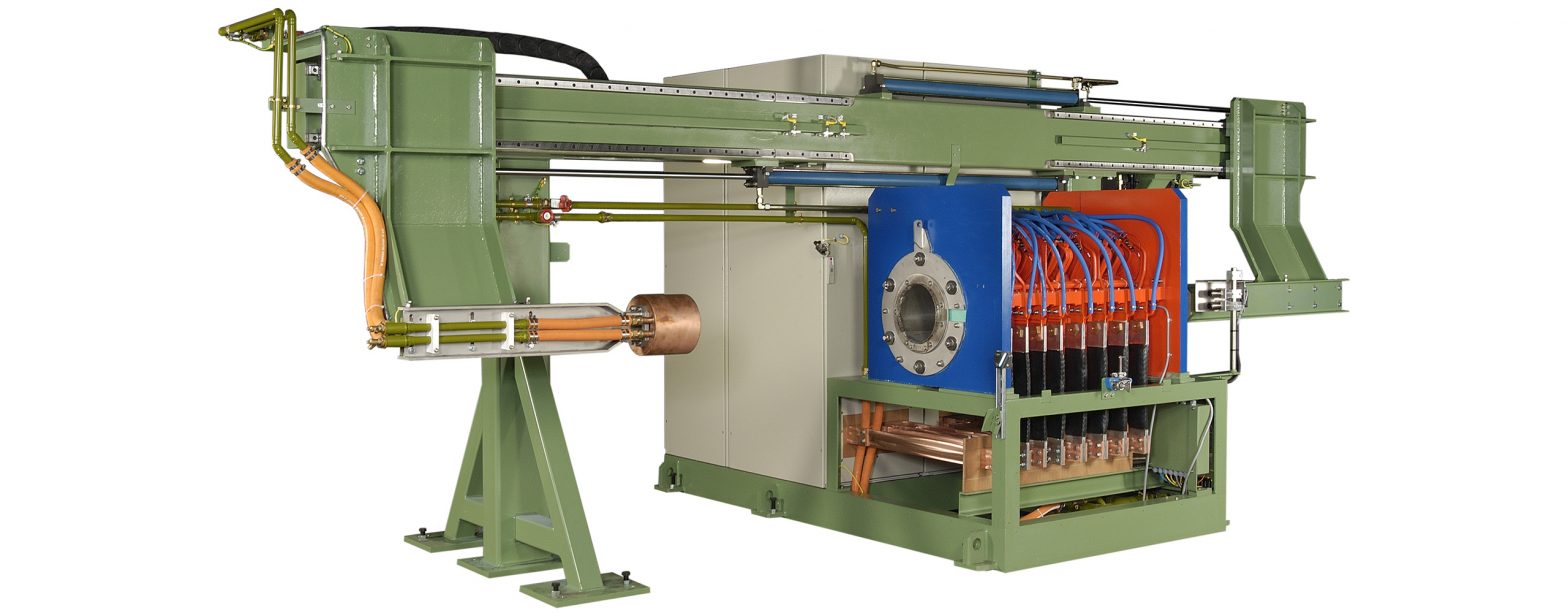

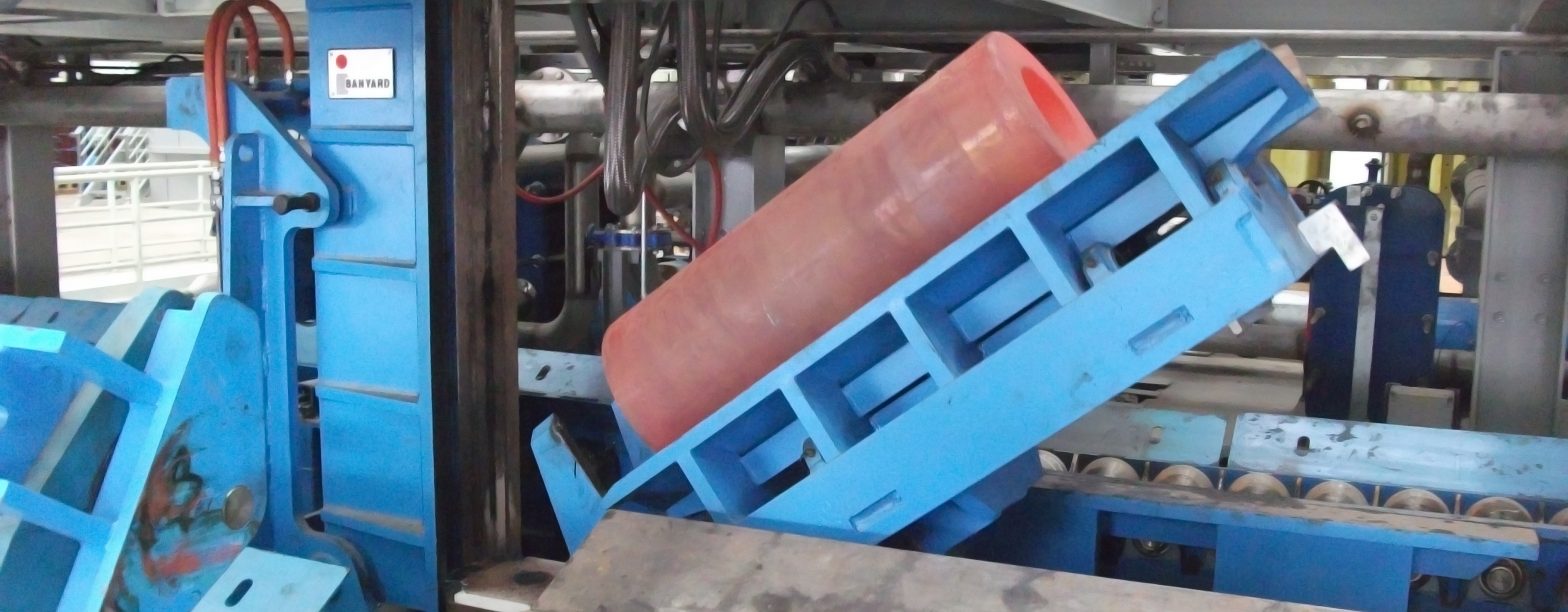

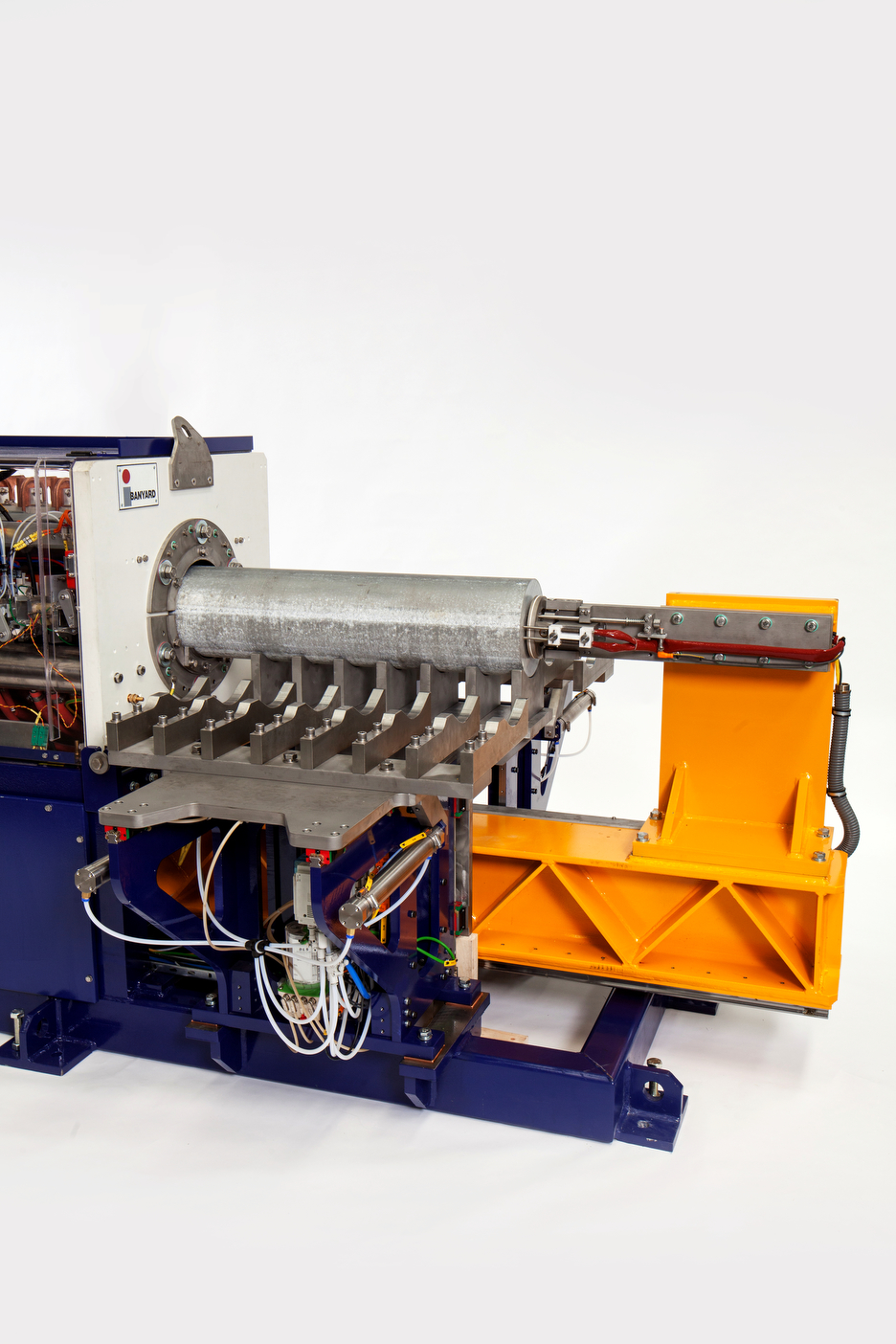

The Banyard Zero Friction Aluminium Billet Heater has been developed over a number of years to provide extruders of aluminium micro tubing with billet heating and handling with minimum impact surface damage resulting in higher quality extruded material.

The Banyard ZF product is enhanced with improved servo-drive technology and now finds extended application in emerging high quality extrusion requirements such as required in the automotive sector.

Features

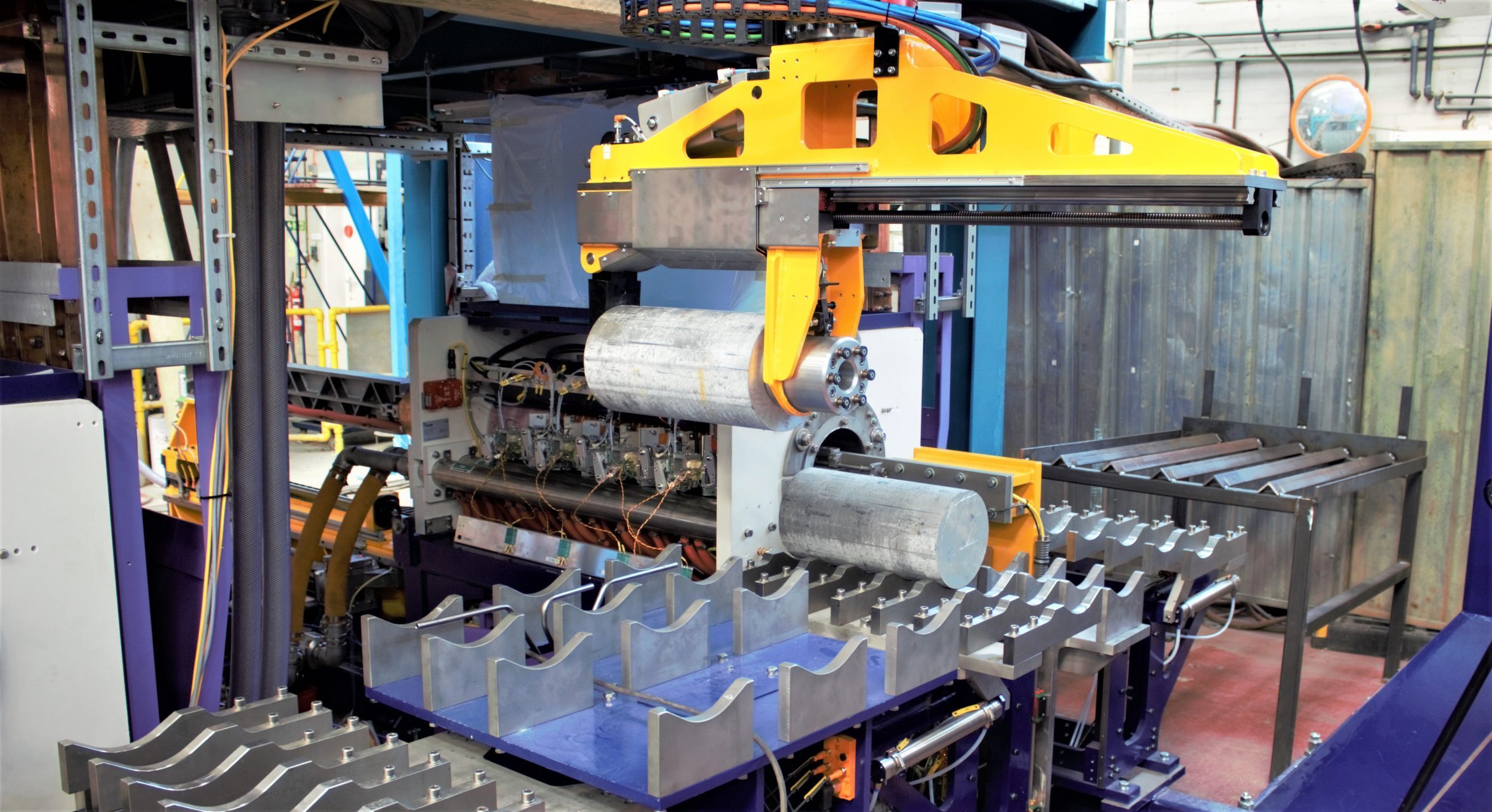

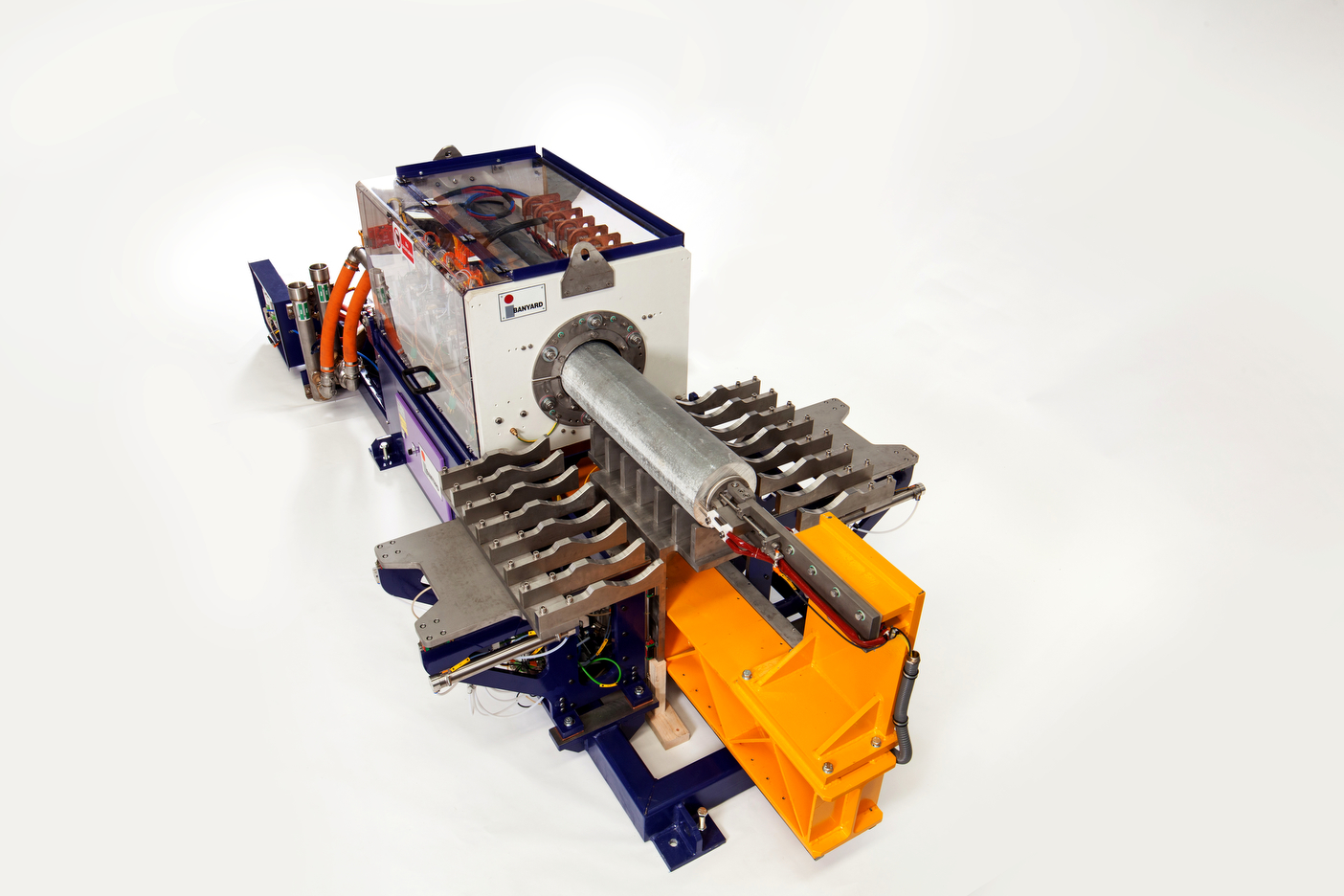

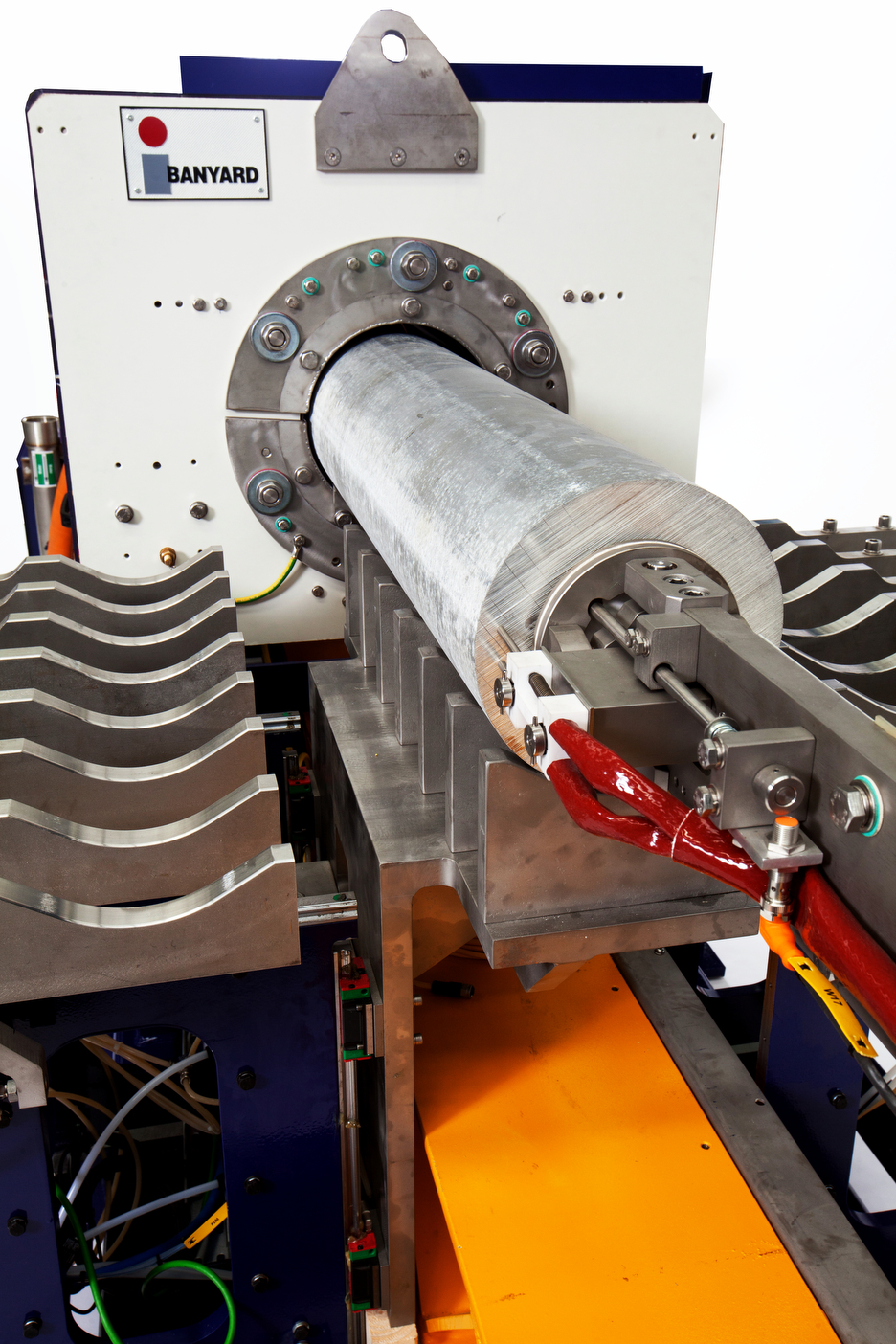

- The Banyard solution provides zero friction servo-handling of the Aluminium billet.

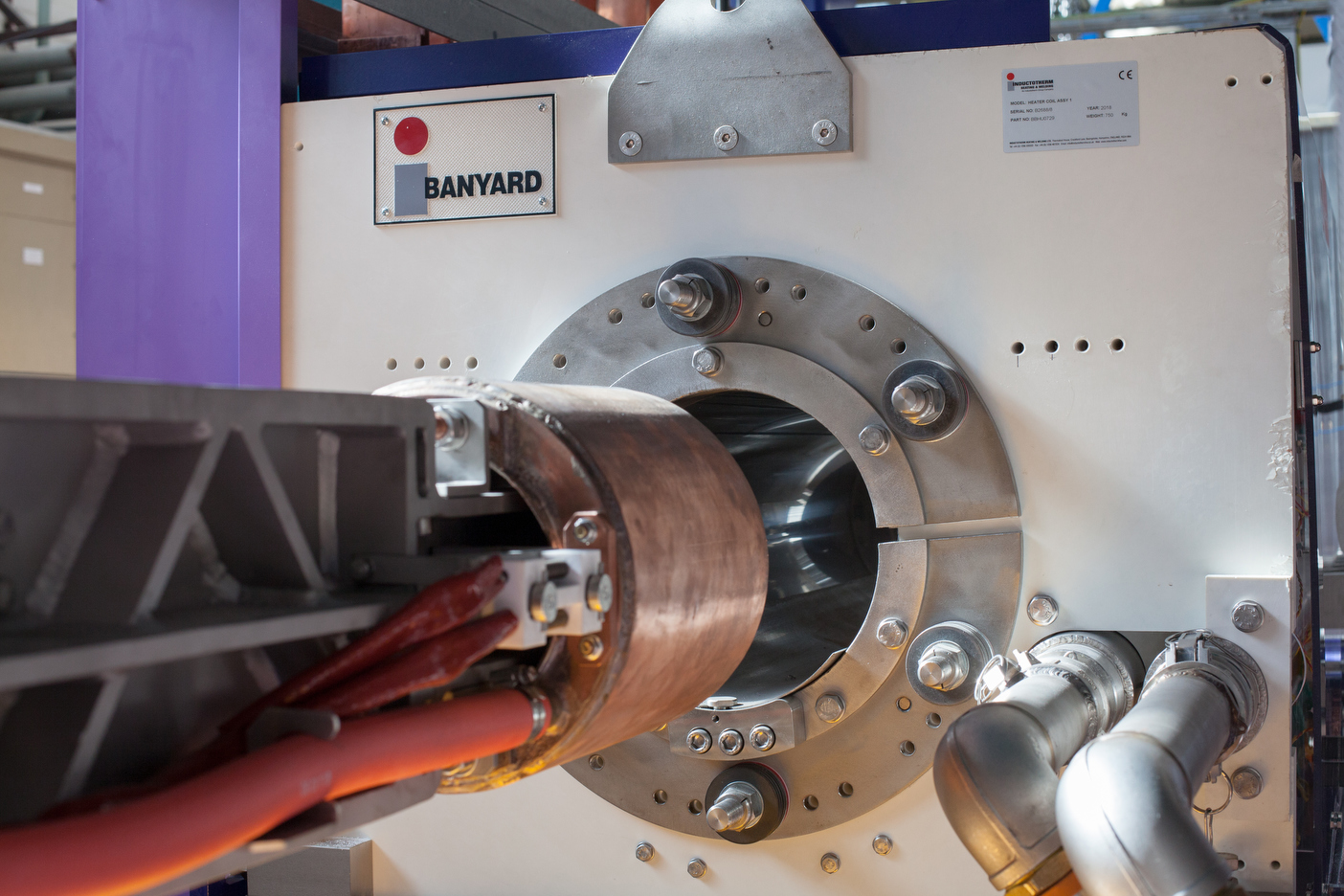

- This is achieved by effectively minimising the area of contact with the billet at all stages of the process by end clamping.

- Smooth movement is also assured by use of precision linear bearings and hardened slide-ways with racks for servo-motor drives.

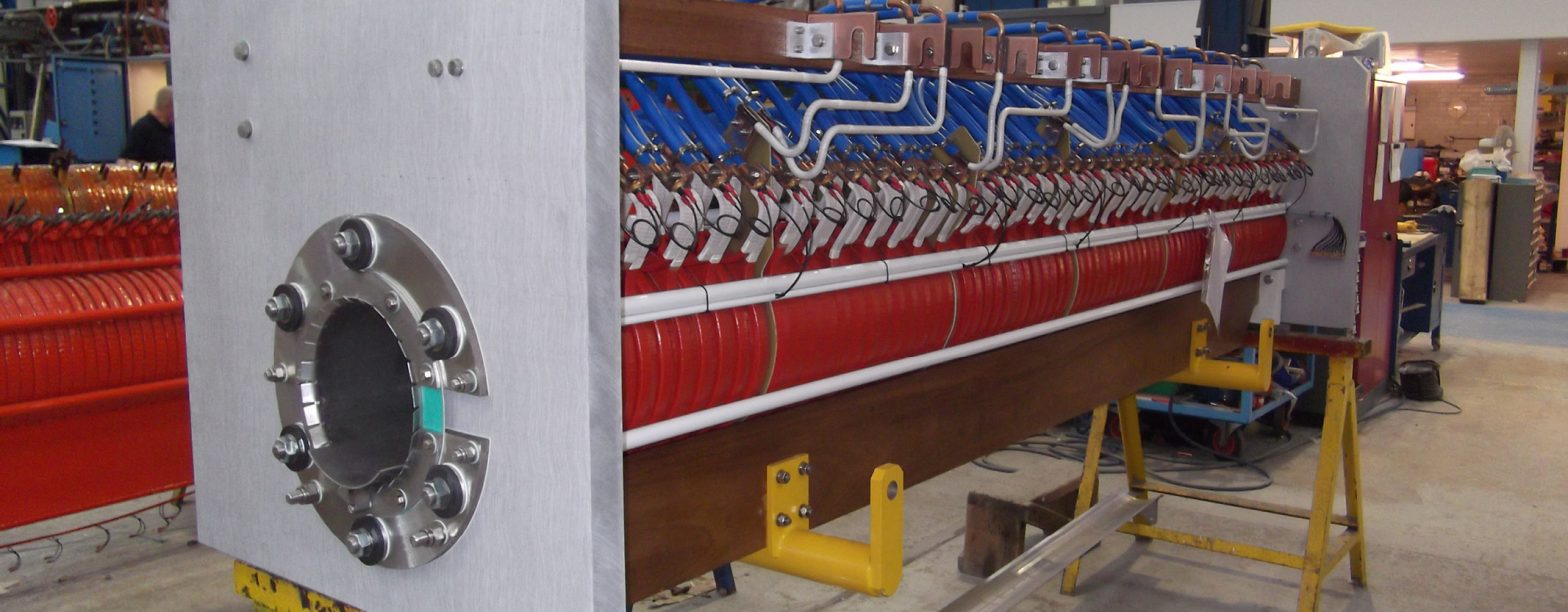

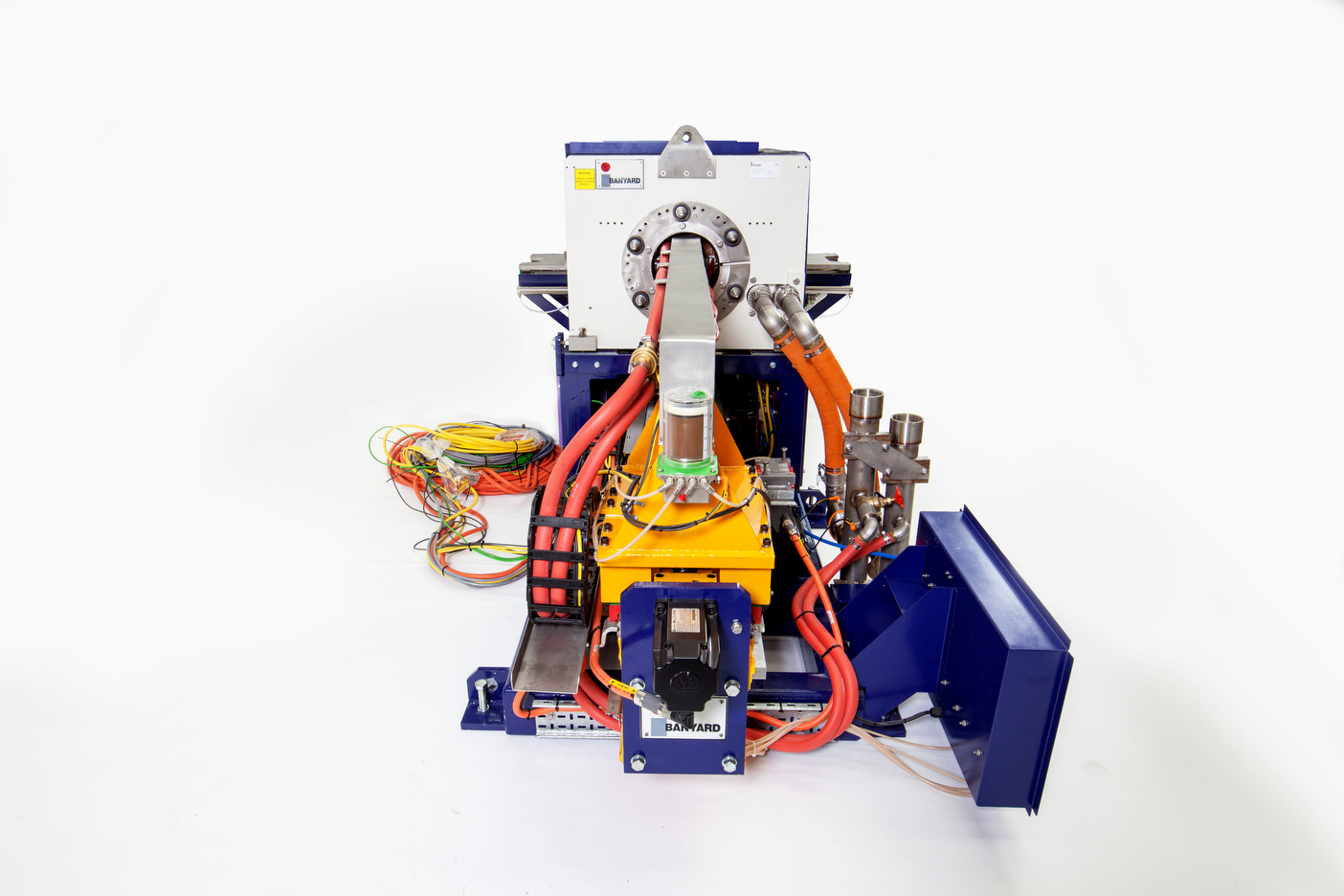

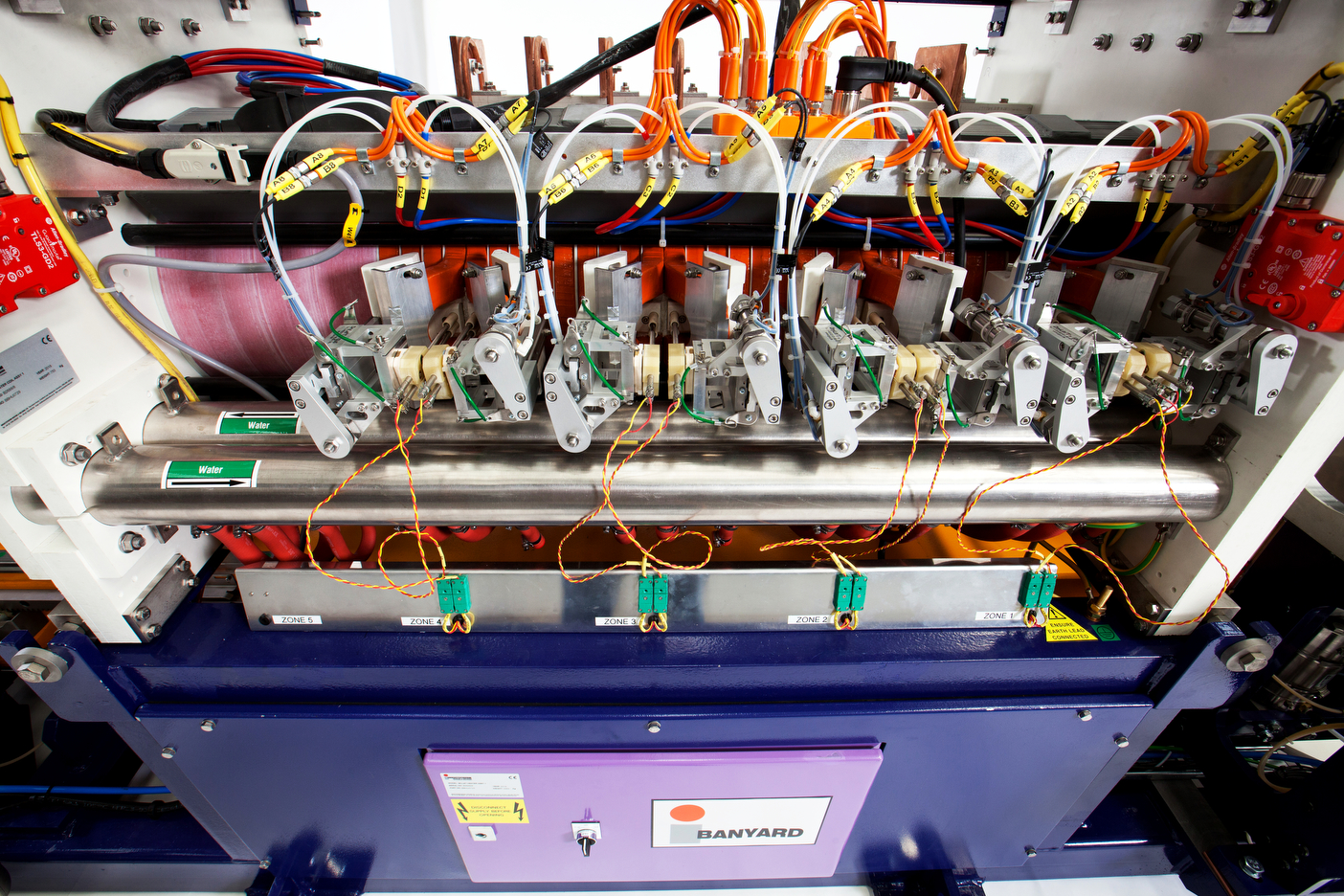

- Multiple Power Convertor and induction coil control zones allow precision billet heating with the capability of variable linear temperature gradients along the billet length, thus reducing press force and die wear.

- Multi-layer induction coils offer high operating efficiency and precise temperature control.

Tech Specs

- Reduced mechanical loads on the coil.

- Eliminates the need for consumable skid plates.

- Available for a billet diameter range 178mm (7”) to 457mm (18”). Other diameters can be considered.

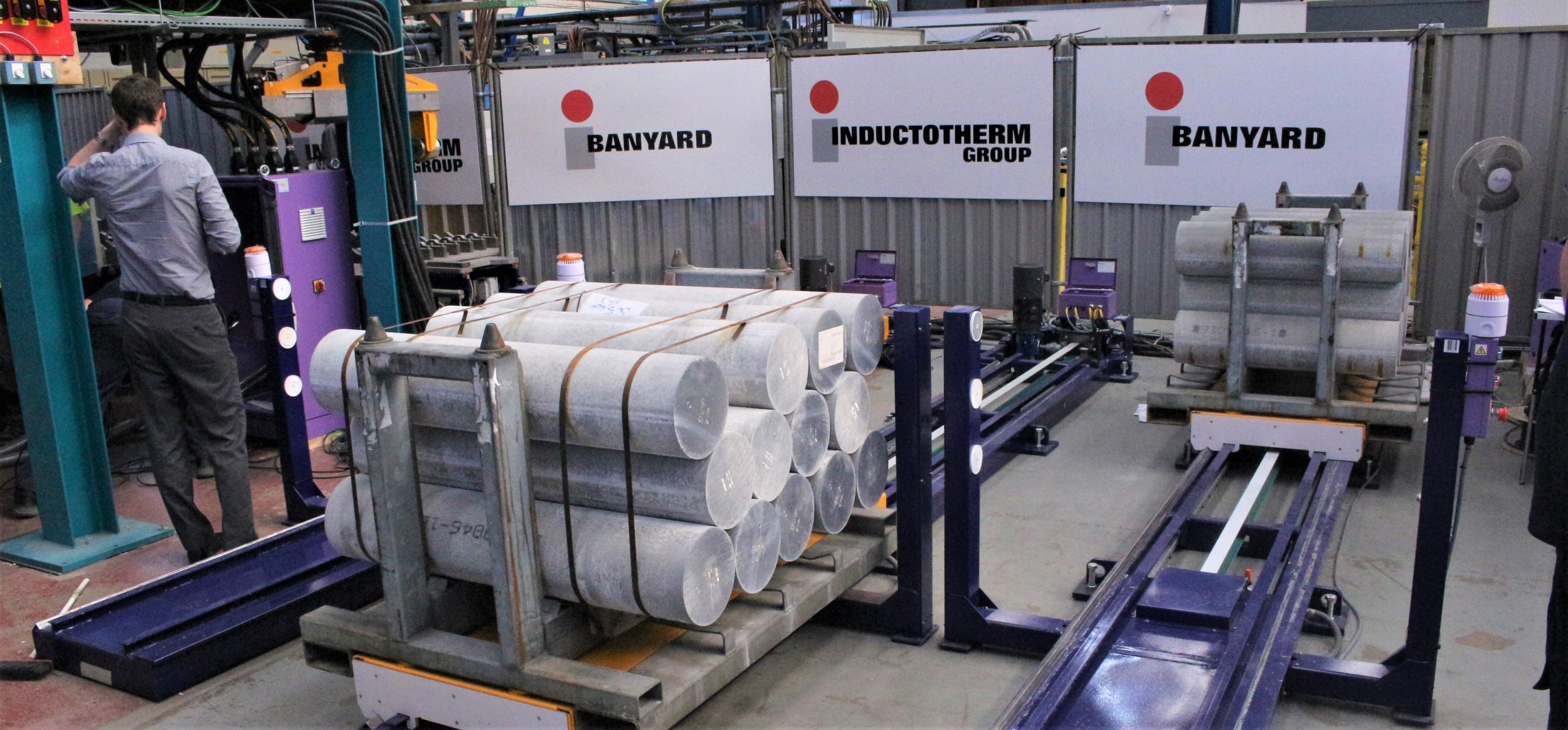

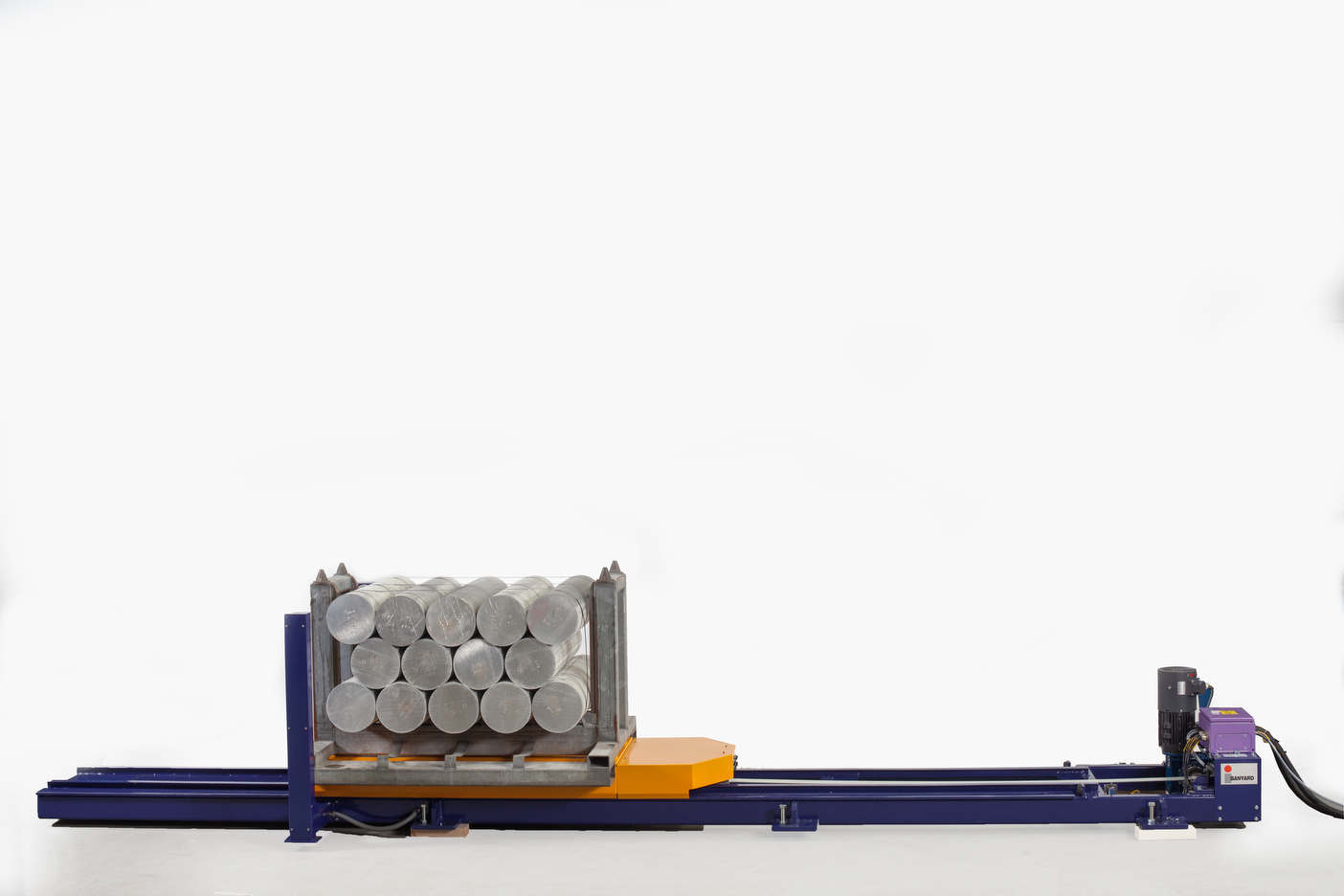

- The heaters are configured as single billet heating.

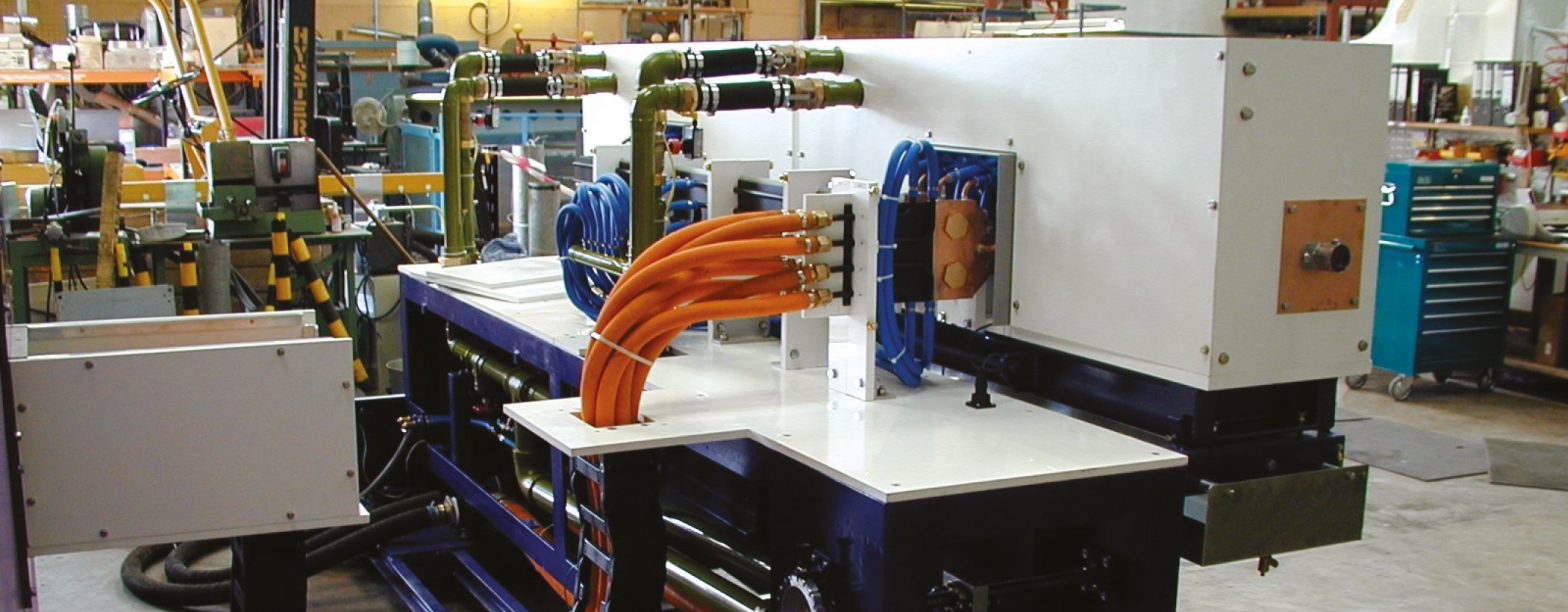

- The required LFi Frequency Power Convertor (frequency range 30 – 200 Hz) can be located adjacent to the induction coil or mounted on a deck above the induction coil to reduce floor footprint.

- For high production volumes single billet heaters can be located in parallel.

- All heater configurations can include overhead manipulators for transportation of hot and cold billets between upstream saws or shears and the downstream quench or press loader.

The equipment quoted herein is uniquely protected by the following patents and in other countries.

European Patents EP2 236 005 B1 and United States Patent No. US10 034 331 B2 for method and apparatus.

Inductotherm reserves all rights in equipment design and methods of utilisation thereof, except those granted to buyer by operation of law. Inductotherm grants no rights to buyer for manufacture or reconstruction of proprietary assemblies or components thereof. All prints and drawings furnished at any time by Inductotherm are for maintenance and repair only

Literature

Literature