Alpha Blades & Jaw Sets

Tube Cutting and Alpha Shear

Inductotherm Heating & Welding offers a comprehensive range of tube cutting consumables, designed specifically for use with its range of Thermatool Alpha high speed flying shears. The Alpha range is available in four models, namely 2”, 3”, 4” and 5” machines.

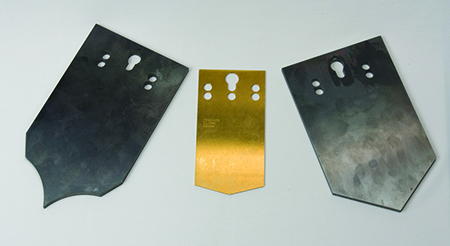

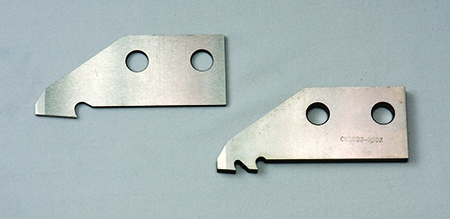

High quality tube shearing relies upon good installation and set-up procedures. To achieve this, it is essential that all cutting consumables such as blades and jaw sets are of the very highest quality. Blade tolerances after hardening are typically within +/- 0.001” (0.025mm) on width and thickness, and less than +/- 0.002”

(0.05mm) on flatness. Blades typically undergo special surface coating and custom heat treatment in order to arrive at the ideal specifications for high speed cutting of exotic materials.

There are many different styles and shapes of blade, the selection of which depends primarily on whether rounds, squares, rectangles or irregular profiles are being precision cut. Thermatool’s unique material delivers increased cutting life on carbon steels and offers exceptional performance when cutting high tensile and stainless steels.

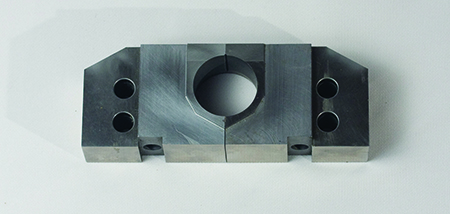

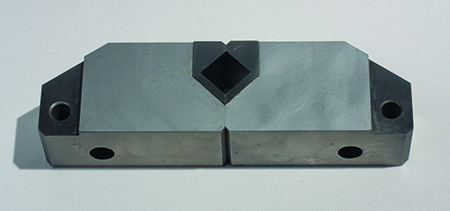

ALPHA Shear Jaw Sets

Alpha jaw sets are available for the cutting of tube with diameters ranging from 10mm to 127mm. They are precision manufactured from highest quality tool steel. Their function is to accurately clamp the tube in the dieset during the high speed cutting process. In addition to providing 50% of the effective cutting surface, they also ensure that correct clearance is maintained between the jaws and the vertical blade, thus enabling the optimum cut (shear) quality to be achieved.

Alpha jaws undergo complex heat treatment to ensure high wear resistance.

Jaw sets can be produced to enable precision cutting of round, square and rectangular tube.

ALPHA Shear Blades

We can supply both Vertical and Horizontal blades to precision cut tube of varying diameter, wall thickness, material composition and Rockwell hardness.

Our Engineers utilise the latest solid edge modeling techniques to generate blade profiles which have the optimum blade geometry designed into them for a specific cutting application. Blade life and cut quality can also be optimised where blades undergo special heat treatment and/or surface coating. Please contact us for assistance on specific tube cutting requirements.

For more information about Inductotherm Heating & Welding’s line of consumable products, please contact us or your local Sales Representative, or call our Customer Support on +44 (0) 1256 335 533 or use the request information form below.