Impedor

Inductotherm Heating & Welding offers an extensive range of impedors to satisfy a very diverse range of tube and pipe welding applications. Whether your mill produces small diameter/thin wall tubing or large diameter/heavy wall API line pipe, we have a wide selection of impedors to suit your need. The proper choice of impedor, correctly installed, will play a major part in achieving maximum welding efficiency.

It should also be noted that as the performance of all ferromagnetic materials is a function of temperature, it is critically important that the ferrite core is kept as cool as possible during the tube welding process. Ideally, the temperature of the coolant flowing through an impedor should not exceed 25 deg C.

Standard Through-Flow Impedor

These are the most widely used of all types of impedor, designed to use solid, fluted ferrite rods in order to ensure sufficient cooling. They consist of one or more ferrite cores inside a casing of either ferroglass or silglass.

For correct operation a minimum pressure of 2.75 bar (40 psi) should be maintained to ensure sufficient flow of coolant through the impedor under all but the most extreme welding conditions.

Standard models are available with diameters ranging from 6.5 mm up to 114 mm in lengths of 230, 330 and 432 mm and above.

Return Flow Impedors

These impedors are recommended for welding applications where it is necessary to keep the inside of the tube dry. Coolant enters and exits the impedor through a special coupling and is discharged outside of the tube.

Fitted with end plugs approximately 12 mm thick, it is important to position the end of the impedor around 15 mm past the weld point for the highest efficiency.

Standard models are available with diameters ranging from 10 mm up to 76 mm in lengths of 230, 330 and 432 mm and above.

Exposed Ferrite Impedors

These impedors offer an efficient alternative for smaller diameter tubes as they allow positioning of the ferrite in the welding zone without fear of the casing burning away.

Exposed ferrite impedors are ideally suited for welding hot rolled strip, aluminised or pre-galvanised strip, stainless steel and other difficult materials. They are also the best choice for air or inert gas cooled applications.

Standard models are available with diameters ranging from 8 mm up to 25 mm with a length of 230 mm.

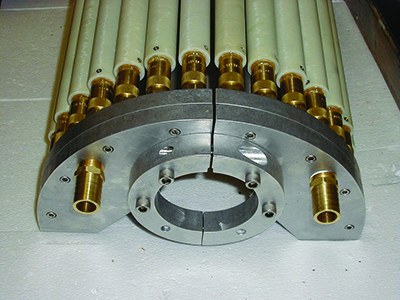

Impedor Cluster Assemblies

Cluster Impedors are recommended for larger tubes and pipes with diameters greater than 102 mm.

They are an assembly of standard impedors connected to a manifold through which the coolant enters.The cluster manifold is supported by the mandrel and fixed into position using a clamp manufactured to suit the customer’s mandrel diameter.

The impedor cluster gives the possibility of economically positioning the ferrite in large tubes without resorting to costly, oversized, single pieces of ferrite. The use of individual standard impedors also enables fast and economical replacement of any damaged parts, as and when required.

On pipe sizes > 200 mm it is not usually necessary for the impedor to completely cover the inside surface of the pipe. Positioned where ferrite is needed, cluster assemblies normally span around 180º of the inside surface of the pipe being induction welded.

For more information about Inductotherm Heating & Welding’s line of consumable products, please contact us or your local Sales Representative, or call our Customer Support on +44 (0) 1256 335 533 or use the request information form below.