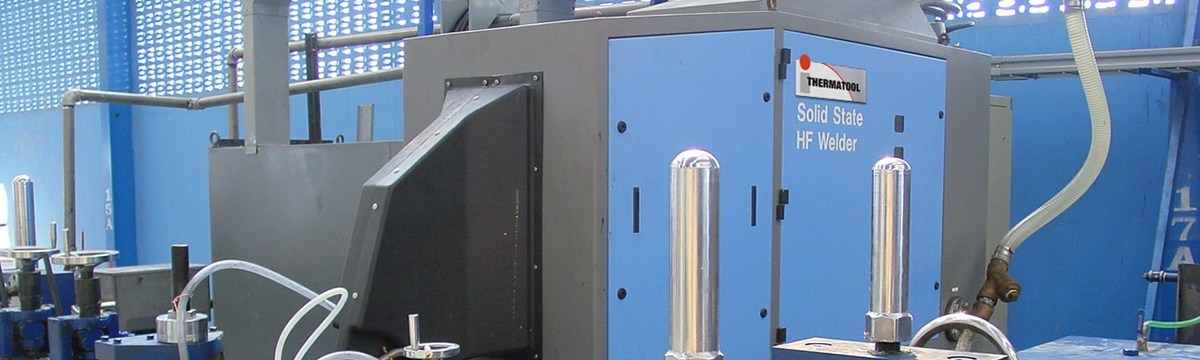

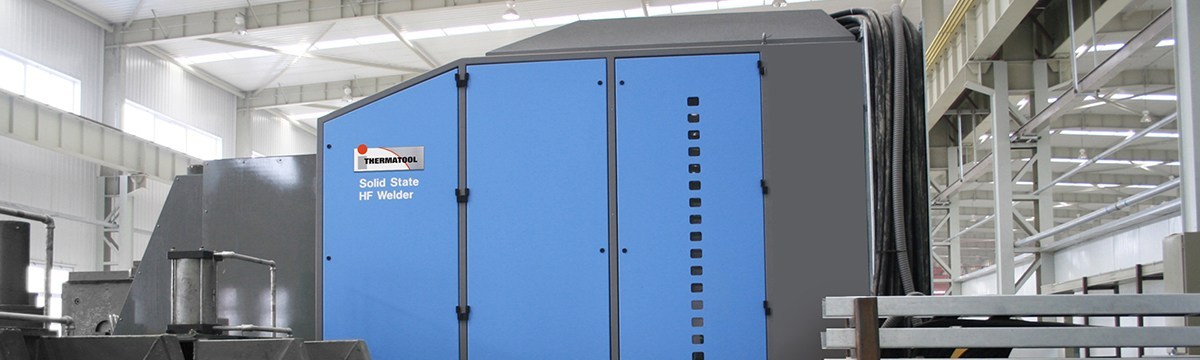

Spiral Fin Tube HF Welders

Produce high quality Spiral Fin Tube efficiently with our Solid State Spiral Fin Tube Welders.

Achieve these excellent benefits with a Spiral Fin Tube Welder:

- Smoother output and improved weld quality

- Weld more alloys more efficiently

- Run higher RPM’s at lower kilowatt voltage

- Less arcing and sparking with improved contact life

- Use less power and water

- Improved safety and less floor space

- Reduction in scrap

Features

- Power Efficiency. Increased output efficiency, resulting in power cost savings

- Reliable. Elimination of expensive finite life components such as the vacuum tube, RF output transformer and tank capacitors adds to increased reliability and up-time, and a significant reduction in maintenance costs.

- Improve DC Ripple. Smoother output wave shape compared to to a vacuum tube welder. Less welder spatter and forge tooling wear.

- Safety. Solid State welders operate at much lower voltages than vacuum tube units – not exceeding 1200 volts at full power assuring added safety operators and maintenance personnel.

- Floor Space. Solid State welders are extremely compact, occupying minimal space. The power supply can be placed up to 1,000 feet away from the mill.

- Improved contact wear. Due to less arcing.

- Reduction in scrap. Due to improved automatic Speed Power Control, reducing unwelded fin areas when stopping and starting.

Tech Specs

| HF Generator | CF 200 | CFS 300 |

| Output power rating | 200KW to Calorimetric Load | 300KW to Calorimetric Load |

| Welding Frequency | 400KHz Normal | |

| Ripple | <1% | |

| Efficiency | 80% Efficient from Line to Load | |

| Description | 4 Pairs of MOS FET Power Modules in RF 12 Enclosure | 6 Pairs of MOS FET Power Modules in RF 12 Enclosure |

| Size | 662 x 2199 x 1045 (mm) | 26 x 87 x 41 (inch) | 662 x 2199 x 1045 (mm) | 26 x 87 x 41 (inch) |

| DC Power Supply and Control Cabinet | ||

| Input Power | 300 KVA at 0.88 Power Factor at Full Power Output | 440 KVA at 0.88 Power Factor at Full Power Output |

| Input Voltage | 480 VAC, 50/60 HZ, 3 Phase, +6% Line Variation, | |

| Others Available | ||

| PLC Type | Allen Bradley SLC 500 Standard, Other Available | |

| Description | PS 2 Enclosure with Internal Power Line Transformer | |

| Size | 2275 x 880 x 2000 (mm) | 90 x 25 x 79 (inch) | |

| Cooling System | ||

| Raw Water Input | 181.0 Litres per min (48 Usgpm) at 30 C (86 F) | 211.7 Litres per min (56 Usgpm) at 30 C (86 F) |

| Raw Water Pressure | 3.4 Bar (50 psi) | |

| Closed Loop Water type | Demineralized, deionized water, pH 7.5-8.5 | |

| Conductivity below 50 micro-Siemens/cm | Conductivity below 60 micro-Siemens/cm | |

| Closed Loop Temperature | 34 C (95 F) Exit Temperature | |

| 45 C (113 F) Inlet Temperature Max | ||

| Temperature Regulator | Primary water circuit flow regulating valve | |